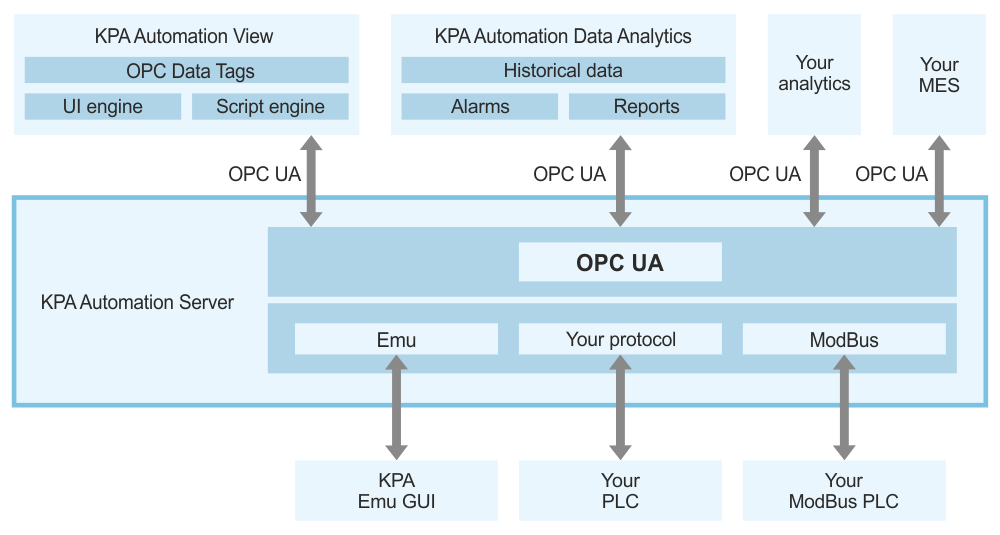

KPA Automation Server collects data from various controllers, aggregates it and transfers it via the secure OPC UA protocol.

KPA Automation Server includes Configuration Utility that provides the possibility to connect device tags with front-end tags and supports multiple back-end plug-ins with their own control sets. Configuration Utility is designed for creating and editing a configuration file that contains tag data.

KPA Automation Server uses the configuration file to create tags, displays the OPC UA interface, launches the back end, and sets up communication between the front end and the back end.

New Features in versions

Unified controller gateway and data provider

KPA Automation Server integrates even old field devices and controllers into modern IT infrastructure and provides aggregated data for various applications, such as:

- Software solutions for creating Human Machine Interfaces (HMI), for example, KPA Automation View

- Data analytic applications, for example, KPA Automation Data Analytics

- Manufacturing Execution Systems (MES)

Secure data transfer

Data is transferred through the OPC UA protocol, which establishes a secure channel between the client and the server using encryption, signatures, and digital certificates.

Flexible development solution

KPA Automation Server can be integrated or used as a standalone application.

Extended capabilities by custom plug-in creation

Plug-ins can be created using the software development kit (SDK) specially designed to enhance communication with specific devices.

A plug-in for KPA Automation Server is a library file in the .dll format that provides anything needed to work with a custom device. It can be created by developers with basic programming skills using .NET Core.

Ready for Industry 4.0

Industry 4.0 refers the concept of fully automated digital production and data exchange in manufacturing technologies and processes. Technology of secure data transfer between any types of devices, provided by KPA Automation Server, entirely complies with the Industry 4.0 concept.

Independent development workflows for HMI and PLC

KPA Automation Server uses configuration files created in Configuration Utility for building an OPC UA tag tree and connecting data sources (devices or applications), which use other access protocols, to OPC UA tag tree nodes. The data tag tree can be either manually created in Configuration Utility without participation of PLC or can be imported from PLC into KPA Automation Server. The imported data tag tree is protected from any changes in PLC.

Data source emulation for HMI debugging and troubleshooting

For HMI debugging and troubleshooting, KPA Automation Server provides the Simulation plug-in that generates data by source emulation to check tags values.